Comgate is a custom mill house specializing in architectural woodwork like wall paneling and custom cabinets. Comgate is creating this business plan to bring its mission statement into clearer focus, after experiencing initial losses and several thin profit years from competitive bidding construction projects. Previously, Comgate bid on as many jobs as possible and had thin margins due to flexible pricing policies. However, with increasing sales, Comgate now has the opportunity to create greater margins, increase efficiency, and improve overall profitability through restructuring and focusing on the target market. These changes will ensure more accurate pricing, billing, and cost tracking for comparison purposes, leading to expected profit increases.

Comgate’s mission is to compete profitably in the high-end residential market for custom woodwork within Connecticut. The company will focus on the highest quality custom work and specialize in the demanding needs of new and remodeled designer homes in the $3 to $15 million price range.

Comgate engages in custom architectural woodwork, including wall paneling, custom cabinets, molding, pilasters, radius units, circular staircases, dressing rooms, and specialty kitchen work. The recent addition of state-of-the-art CAD capability will help increase sales of higher-end products by targeting design professionals who can influence subcontractor choices for "trophy" homes costing over $3 million. Comgate only produces custom woodworking made to order, with no finished goods stocked. Production runs are rarely very long.

The industry is mature and well-represented, with many mill shops in the same market area specializing in different areas. Comgate targets the highest end of the residential market and focuses on its CAD capability as a critical competitive advantage. By linking CAD capability with design professionals’ practices, Comgate plans to outsource simpler parts to other mill shops while keeping challenging work in-house. Detailed CAD drawings will facilitate this and allow Comgate to increase sales and profits while concentrating on custom woodwork.

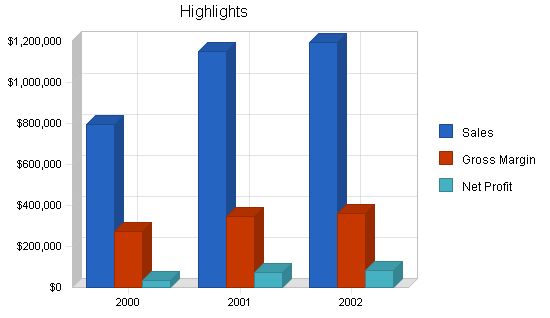

Financially, Comgate projects sales to reach nearly $800,000 by the end of Year 1 and $1.2 million by the end of Year 3 due to the recent addition of advanced CNC machinery and in-house industry-adapted CAD capability. Profitability will also increase. The company plans to shorten accounts payable in Year 2 to take advantage of trade discounts, which will require increased bank lines of credit of approximately $30,000.

Comgate has a mission to compete in the high-end residential custom woodwork market in Connecticut. They focus on providing the highest quality custom work and specialize in the demanding needs of new and remodeled designer homes priced between $3 and $15 million.

The key to success in the contractors’ mill shop industry includes avoiding bidding on projects primarily based on price, projects by disreputable individuals, projects that are too large, or projects that don’t align with the company’s niche market. Other important factors include accurate take-off and listing, clear communication with clients regarding quality and payment terms, correct calculation of material and labor requirements, proper application of overhead factors and profit margins, and considering any special considerations.

Comgate’s objectives include increasing production by reaching 80% of full capacity in the last quarter of Year 1, 85% in Year 2, and 90% in Year 3. Monthly production goals include 342 feet of crown molding, 22 pilasters, 54 doors, and 77 linear feet of cabinets. They aim to maintain site contract workers at present levels, continue efforts to promote their in-house CAD capability to design professionals, join industry organizations like ASID and CSA, complete administrative changes to improve billing and cost tracking, and finalize an operations manual.

Comgate has adjusted its mission statement to focus on profitability and serving the needs of design professionals. They have implemented CAD capacity to attract more work and improve pricing. With increased business, they plan to restructure their administrative processes for better efficiency and accuracy. The company’s profits are expected to remain in the black and increase.

Comgate is a limited liability S corporation owned by Andrew Comins since 1996.

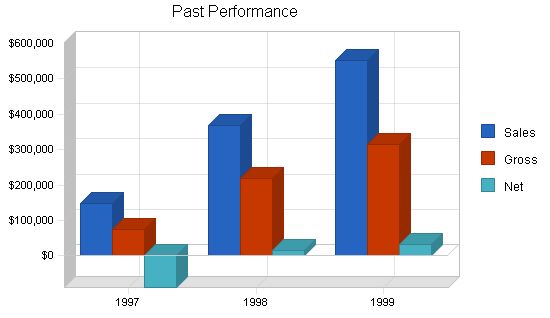

The company’s history includes a standard chart and table of their performance. Appendix A provides an in-depth analysis of past performance compared to similar mill shops. Appendix K has been omitted from this plan presentation.

Past Performance:

1997 1998 1999

Sales $147,481 $367,305 $552,864

Gross Margin $73,591 $218,102 $313,702

Gross Margin % 49.90% 59.38% 56.74%

Operating Expenses $162,547 $195,639 $260,251

Collection Period (days) 0 20 66

Inventory Turnover 4.80 35.10 9.90

Balance Sheet:

1997 1998 1999

Current Assets

Cash $25,563 $13,763 $3,988

Accounts Receivable $0 $39,412 $161,313

Inventory $7,949 $14,337 $6,500

Other Current Assets $1,650 $0 $0

Total Current Assets $35,162 $67,512 $171,801

Long-term Assets

Total Long-term Assets $56,933 $40,421 $35,310

Total Assets $92,095 $107,933 $207,111

Current Liabilities

Accounts Payable $5,283 $16,058 $58,344

Current Borrowing $9,143 $11,857 $69,477

Other Current Liabilities (interest free) $3,829 $25,288 $10,000

Total Current Liabilities $18,255 $53,203 $137,821

Long-term Liabilities $161,433 $125,720 $99,179

Total Liabilities $179,688 $178,923 $237,000

Paid-in Capital $2,000 $2,000 $2,000

Retained Earnings ($637) ($89,593) ($65,014)

Earnings ($88,956) $16,603 $33,125

Total Capital ($87,593) ($70,990) ($29,889)

Total Capital and Liabilities $92,095 $107,933 $207,111

Other Inputs

Payment Days 30 39 89

Sales on Credit $147,481 $367,305 $552,864

Receivables Turnover 0.00 9.32 3.43

2.3 Company Locations and Facilities

The company is located in New Haven, Ct. in rented facilities. Total area is 2,500 square feet, with 100 square feet used for administration. Expansion is possible by renting another 1,600 square feet of adjoining space in January 2000 at an additional monthly rent of $2,000. A production hall diagram can be found in Appendix G.

Note: Appendices A – K have been omitted from this sample plan presentation.

Products and Services

The products used in this plan are limited to five items for simplicity. Comgate specializes in custom woodworking and does not carry finished goods in stock. There are rarely long production runs.

3.1 Product and Service Description

Comgate specializes in custom architectural woodwork such as wall paneling, custom cabinets, moldings, and pilasters. Most products fall into a few general categories, but the company aims to move more up-market within the high-end residential market by producing unique and challenging work. The addition of CAD capability allows for targeting design professionals in the luxury home market.

3.2 Competitive Comparison

Performing a competitive comparison with other mill shops is difficult as each product is custom-made. However, financial comparisons can be made with a group of mill shops in the New Haven area. The market study estimates that the demand for custom wood millwork in the high-end residential market is equal to the total supply available. Comgate’s CAD capability gives the company a competitive advantage in this market.

Note: Appendices A – K have been omitted from this sample plan presentation.

3.3 Sales Literature

No sales literature is currently available. Brochures will be produced once production capacity is expanded and management gaps are filled.

3.4 Fulfillment

All materials used in production can be sourced from local suppliers, primarily lumber dealers.

3.5 Technology

Technology plays a role in the woodworking industry, with modern machinery incorporating time and labor-saving advantages. Comgate has invested in new CNC equipment and CAD capabilities to increase production and cater to the high-end market.

3.6 Future Products and Services

Comgate plans to focus on producing more challenging and unique woodwork, such as radius units, staircases, and elaborate kitchens and libraries in exotic woods. Some less complex sections of projects may be outsourced. The financials of this business plan do not reflect profits from outsourcing.

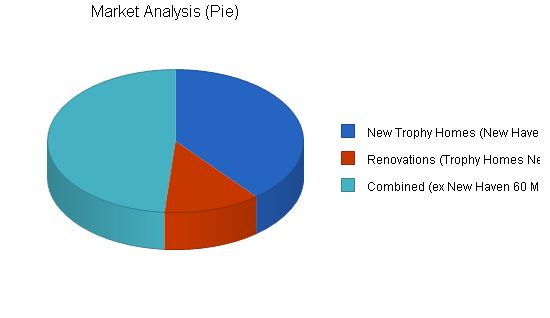

Market Analysis Summary

The highest end of the residential market consists of new construction and the renovation of high-end homes in the $3-$15 million price range. The New Haven area alone has an annual demand for custom woodwork products of approximately $13 million. Additional demand is generated by homes located within 60 miles of New Haven.

4.1 Market Segmentation

The market for custom woodworking is driven by new construction and residential remodeling. Baby Boomers, comprising almost 45% of the American population, are the strongest market for home improvements and high-end custom woodwork. The New Haven area sees annual expenditures of over $1.9 billion on new single family homes and $627 million on major renovations. The demand for custom woodwork exceeds supply in this market.

Note: Appendices A – K have been omitted from this sample plan presentation.

Market Analysis

| Market Analysis | |||||||

| 2000 | 2001 | 2002 | 2003 | 2004 | |||

| Potential Customers | Growth | CAGR | |||||

| New Trophy Homes (New Haven) | 2% | 96,775 | 99,098 | 101,476 | 103,911 | 106,405 | 2.40% |

| Renovations (Trophy Homes New Haven) | 2% | 30,000 | 30,720 | 31,457 | 32,212 | 32,985 | 2.40% |

| Combined (ex New Haven 60 Miles) | 2% | 120,000 | 122,880 | 125,829 | 128,849 | 131,941 | 2.40% |

| Total | 2.40% | 246,775 | 252,698 | 258,762 | 264,972 | 271,331 | 2.40% |

Contents

4.2 Target Market Segment Strategy

In line with Comgate’s mission statement, the target market is trophy homes, both new construction and renovations. Our market study indicates that the high-end trophy home market in the New Haven area requires custom woodworking services that are currently undersupplied by local suppliers. To compete in this sector, Comgate offers a successful CAD service for design professionals. This CAD service is further explained in the chapter on Market Needs. The custom millwork products supplied by Comgate are needed in all three high-end market sectors. These construction projects, whether new construction or major renovation, require design professionals of the highest standards and clients with substantial budgets. The work in this market is relatively recession-proof. Clients in this market have demanding requests for custom woodworking products, which align with Comgate’s mission statement and capabilities.

4.2.1 Market Trends

With increasing demand for high-end trophy home construction and the difficulty of attracting and retaining skilled workers, Comgate has linked its CAD capability with the practices of design professionals. This allows the company to outsource simpler parts of a project to other mill shops while focusing on the more challenging work themselves. By providing detailed CAD drawings, dimensions, and material lists to other mill shops, Comgate can increase sales and profits while concentrating on custom woodwork products.

4.2.2 Market Growth

Market growth of 2.4% is based on the actual growth rate in building permits in the East from 1997-1999, as tabulated by the U.S. Census.

4.2.3 Market Needs

Comgate’s new CAD service was developed to address inefficiencies observed in the past. One major problem was the discrepancy between blueprints and final designs. The new CAD service allows Comgate to work closely with architects at the initial stages, reducing drafting costs, problem-solving, and re-drafting. Clients benefit from woodwork that suits the latest woodworking methods while maintaining the design concept. Comgate also saves on-site measuring expenses.

4.3 Service Business Analysis

The industry is mature and well-represented, with many mill shops in the same market area, each specializing in different areas of woodworking. Comgate distinguishes itself by focusing on the highest-end residential market and offering CAD expertise. This allows the company to fully utilize its expanded production capacity.

4.3.1 Distributing a Service

In this industry, the traditional distribution pattern involves architects drafting plans, contractors bidding on projects, and subcontracting elements like millwork to mill shops. However, Comgate’s marketing strategy alters this pattern by working closely with design professionals. This saves time and money for architects, eliminates change orders for contractors, and ensures that Comgate receives the work without competitive bidding.

4.3.2 Business Participants

Major competitors in the Greater New Haven area include Hamden Woodworks, Inc., Custom Design Woodwork, J. Peterman Woodworking, and The Joinery Shop. Appendix B provides a map showing the locations of mill shops in the area. However, none of these mill shops have the same level of CAD capability, and few focus specifically on the trophy home market.

Strategy and Implementation Summary

To enter the trophy home market in the Hartford area, Comgate will target architects and interior designers renowned for residential work in the $3-$15 million price range. The company will adhere to its new costing/pricing method and implement recent administrative control and reporting changes.

5.1 Sales Strategy

To ensure a profitable margin and successfully close sales, the owner, Andrew Comins, personally handles the sales process. To maximize his time networking with design professionals, he relies on the office manager to handle administrative tasks and a production manager to maintain efficient operations in the plant. Important aspects of closing the sale include clearly stating the scope of work, setting a mutually agreed schedule, defining payment terms, and providing a clear price breakdown. A log should be kept of all bidding efforts and follow-up is essential.

Performing a SWOT analysis is essential for developing effective business strategies. Check out our free guide and template for conducting a SWOT analysis.

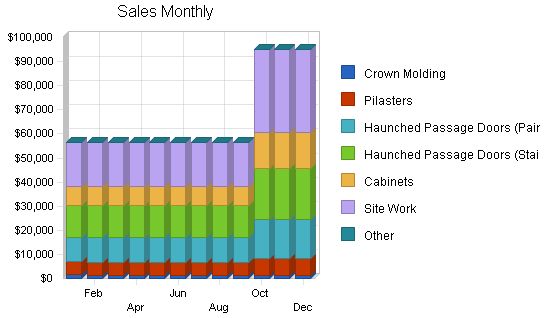

5.1.1 Sales Forecast

Comgate generates revenue from plant-produced sales and contract site labor. For plant-produced sales, representative items such as crown molding, pilasters, doors, and cabinets have been chosen to project revenue. The labor hours and material costs for each item have been calculated. Appendix C provides a detailed breakdown of materials and labor costs for these items. Comgate’s yearly full production capacity for these items is projected based on a 160 man-hour per week limit. For contract site labor, six workers are listed with their costs and billing rates. The sales forecast is based on projected unit sales and average sales prices, with assumptions for production efficiency and work hours.

Note: Appendices A – K have been omitted from this sample plan presentation.

| Sales Forecast | |||

| 2000 | 2001 | 2002 | |

| Unit Sales | |||

| Crown Molding | 4,239 | 4,356 | 4,612 |

| Pilasters | 219 | 279 | 295 |

| Haunched Passage Doors (Paint Grade) | 234 | 348 | 369 |

| Haunched Passage Doors (Stain Grade) | 234 | 348 | 369 |

| Cabinets | 591 | 785 | 831 |

| Site Work | 7,647 | 11,760 | 11,760 |

| Other | 0 | 0 | 0 |

| Total Unit Sales | 13,164 | 17,876 | 18,236 |

| Unit Prices | 2000 | 2001 | 2002 |

| Crown Molding | $4.02 | $4.00 | $4.00 |

| Pilasters | $316.96 | $316.96 | $316.96 |

| Haunched Passage Doors (Paint Grade) | $592.35 | $592.35 | $592.35 |

| Haunched Passage Doors (Stain Grade) | $783.09 | $783.09 | $783.09 |

| Cabinets | $194.76 | $194.76 | $194.76 |

| Site Work | $35.33 | $35.33 | $35.33 |

| Other | $0.00 | $0.00 | $0.00 |

| Sales | |||

| Crown Molding | $17,027 | $17,424 | $18,448 |

| Pilasters | $69,414 | $88,432 | $93,503 |

| Haunched Passage Doors (Paint Grade) | $138,610 | $206,138 | $218,577 |

| Haunched Passage Doors (Stain Grade) | $183,243 | $272,515 | $288,960 |

| Cabinets | $115,103 | $152,887 | $161,846 |

| Site Work | $270,169 | $415,481 | $415,481 |

| Other | $0 | $0 | $0 |

| Total Sales | $793,566 | $1,152,876 | $1,196,815 |

| Direct Unit Costs | 2000 | 2001 | 2002 |

| Crown Molding | $2.00 | $1.82 | $1.82 |

| Pilasters | $48.25 | $44.09 | $44.09 |

| Haunched Passage Doors (Paint Grade) | $142.05 | $130.53 | $130.53 |

| Haunched Passage Doors (Stain Grade) | $269.76 | $247.88 | $247.88 |

| Cabinets | $62.40 | $57.66 | $57.66 |

| Site Work | $25.74 | $27.69 | $27.69 |

| Other | $0.00 | $0.00 | $0.00 |

| Direct Cost of Sales | |||

| Crown Molding | $8,486 | $7,928 | $8,394 |

| Pilasters | $10,566 | $12,301 | $13,007 |

| Haunched Passage Doors (Paint Grade) | $33,240 | $45,424 | $48,166 |

| Haunched Passage Doors (Stain Grade) | $63,123 | $86,262 | $91,468 |

| Cabinets | $36,878 | $45,263 | $47,915 |

| Site Work | $196,871 | $325,634 | $325,634 |

| Other | $0 | $0 | $0 |

| Subtotal Direct Cost of Sales | $349,165 | $522,813 | $534,584 |

5.2 Marketing Strategy

The marketing strategy, as explained in other chapters, is to leverage Comgate’s CAD capability to increase high-end work with design professionals (interior designers and architects). To find the best interior designers, it is recommended to speak to the designer workrooms that carry out work for window treatments, fabrics, etc.

The best known workrooms in and around New Haven are:

- Fall Creek Sewing.

- Andrew Smith.

- Fortress Lines.

- Jones & Jones.

- Forefront.

- S. Brandt & Company.

- Tapper Works.

A polling of these workshops indicates the following interior designers are often sought by trophy home owners:

** Names have been removed for confidentiality.

Architects are another important group of design professionals that work with interior designers on trophy homes. The Directory of Architectural Firms in Connecticut lists 750 architectural firms, with about 300 specializing in residential work. It would be beneficial to find out which residential architects are located in areas of New Haven with the greatest concentration of trophy homes.

5.2.1 Positioning Statement

Comgate’s CAD capability allows for the practical and efficient construction of custom woodworking while preserving the design concept. It automatically calculates dimensions and produces material lists, enabling simpler elements to be subcontracted to other mill shops. This positions Comgate to receive high-end work from architects designing homes in the $3-$15 million bracket, establishing a reputation for quality and challenging work.

5.2.2 Pricing Strategy

The bidding process involves separate mark-ups for materials and labor to accommodate the variations in custom woodwork. An administrative overhead mark-up is calculated based on total administrative overhead expenses divided by total materials and direct labor. A plant overhead mark-up is applied to labor only and is calculated by dividing plant overhead costs by direct labor. The total anticipated costs, after application of the overhead factors, are divided by 0.85 to include a 15% profit margin.

An Excel spreadsheet designed for costing and pricing incorporates the overhead factors and profit mark-up. It facilitates calculations of materials, labor hours, and up-to-date prices and wage rates.

5.2.3 Promotion Strategy

The best way to promote Comgate’s CAD capability is to directly contact architects and interior designers. Joining the ASID and the CSA as an "Industry Partner" provides networking opportunities. Getting listed in the Resource Directories of these organizations is also recommended.

5.3 Strategic Alliances

Comgate plans to establish strategic alliances with other mill shops to subcontract mundane items, allowing Comgate to focus on more challenging work. Drawings, cut lists, and CNC programming data can be shared with subcontracting mill shops to ensure fast and accurate production.

5.4 Milestones

The table below outlines the strategic milestones for Comgate in the coming years.

| Milestones | |||||

| Milestone | Start Date | End Date | Budget | Manager | Department |

| Complete Administrative Control Changes | 10/1/2000 | 11/30/2000 | $500 | A. Comins | Management |

| Complete Procedures Manual | 10/1/2000 | 10/1/2001 | $0 | A. Comins | Management |

| Join ASID and CSA | 11/1/2000 | 12/30/2000 | $4,000 | A. Comins | Management |

| Get Certification by AWI | 11/1/2000 | 11/1/2001 | $1,000 | A. Comins | Management |

| Hire Production Manager | 4/1/2001 | 5/1/2001 | $60,000 | A. Comins | Management |

| Totals | $65,500 | ||||

Hello!

I’m Andrew Brooks, a seasoned finance consultant from the USA and the mind behind phonenumber247.com.

My career is built on a foundation of helping individuals and businesses thrive financially in an ever-changing economic landscape. At phonenumber247.com, my aim is to demystify the complex world of finance, providing clear, actionable advice that can help you navigate your financial journey with confidence. Whether it’s personal finance management, investment strategies, or understanding the nuances of market dynamics, I’m here to share insights and tools that can propel you towards your financial goals.

Welcome to my digital space, where every piece of advice is a step closer to financial clarity and success!