Recycling Energy Conversion Business Plan

Nationwide, many landfills are closing or exhausting their remaining capacity, yet due to environmental restrictions, zoning laws, and other regulatory and bureaucratic delays, few new landfills are opening to offset the space crisis. Municipal waste continues to flow in greater volume, posing a major problem for most municipalities. With increasing waste, landfills are rapidly facing a capacity crisis – they are akin to owning a reverse gold mine.

Good Earth Resources, Inc. (GER) has been formed to provide a solution for the municipal waste problem in the St. Louis, Missouri area and capitalize on the benefits of possessing fully permitted landfills.

GER will purchase two landfills – one in Eastern Missouri (Martin Creek Landfill) and one in Southern Illinois (Barton Sanitary Landfill) – near St. Louis, Missouri. The initial waste stream for both landfills will come from the St. Louis area.

All waste at both landfills will be sorted and recyclables removed. The remaining waste will be compacted, baled, and buried in the landfills. Currently, only 10% of landfills nationwide perform these functions, ignoring a substantial source of income.

GER will accept direct delivery of waste to its landfills, dispatch its own road tractors for more distant waste, and rail-haul waste from New York City and Chicago. Hauling Missouri waste ensures a steady waste stream for GER to meet its income projections. Initially, GER expects to accept up to 1,540 tons of waste to its landfills daily.

At the landfills, incoming waste will be dumped into receiving facilities designed to contain waste vapors, control vectors, and house machinery. Employee-sorters will remove all paper, cardboard, glass, plastic, and metals, which will be sold for a profit. The remaining waste will be compressed into two-thirds cubic yard bales and stacked in a large, PVC-wrapped cell in the landfill that allows efficient capture of methane gas. Most landfills do not perform these essential tasks.

Removing recyclable materials and compacting the remaining waste adds value to GER’s asset base, the permitted property, by reducing volume and adding to the lifespan of the landfill. It also adds to gross revenues.

Landfills are valued by the volume of waste that can be deposited into the permitted area. By compacting, the deposited volume is increased five-fold. For instance, the Martin Creek landfill permit covers an area of 42 acres to accept 3,612,000 cubic yards. 2,000 cubic yards of loose waste buried daily without compaction would fill the landfill in 6+ years. By recycling, compacting, and baling, 2,000 yards is reduced to 220 cubic yards, extending the lifespan to 32 years. This increases both value and gross income.

The current fee per cubic yard of waste in the St. Louis area is $11.33 ($34.00 per ton). 2,000 cubic yards/day of loose waste generate $35,328,000 in 6+ years. By recycling, compacting, and baling, the same area can be used for 32 years and generates $176,640,000.

GER anticipates collecting 940 tons of waste daily for the Barton landfill in the first months of operations, generating more than $5,500,000 in revenues per year. An additional 600 tons/day for Martin Creek, transported to Barton during Martin Creek’s construction, adds $4,000,000 more. Investors can expect an outstanding annual return as well as ownership in a profitable business with dividends in the first year.

GER will seek other sources of waste, such as New York City, Chicago, and other large municipalities, to augment the waste stream. Rail spurs will facilitate the incoming flow of waste from distant cities.

Within twelve months of commencing operations, GER will collect methane gas and convert it to saleable energy in the form of either electricity sold into the national grid or methanol for sale as a gasoline alternative, augmenting annual revenues.

The principals of GER have extensive experience in every aspect of this business and are founding this company to meet the growing need for landfills in the St. Louis area and to operate a profitable business.

Don Smith, co-founder of GER, has extensive experience in waste collection, landfill operation, and waste handling.

John App, co-founder of GER, has a strong background in finance and marketing and will focus on developing the out-of-state waste stream sources.

G. Calvin Rathbone, Esq. serves as corporate counsel to GER and will also assist in developing out-of-state waste stream sources. Mr. Rathbone’s previous experience includes managerial roles in sales and marketing for a company providing equipment for the exploration and production of oil and gas.

General Plan of Action

The principals of GER are seeking a $16,469,951 net investment to:

1. Purchase both the Martin Creek and Barton landfills.

2. Augment the daily waste stream to Barton landfill by hauling waste.

3. Install sorting and compacting machinery at Barton to maximize landfill lifespan.

4. Complete the construction of Martin Creek landfill.

5. Lease or purchase machinery and vehicles needed for operations.

6. Build two transfer stations to collect waste in Missouri cities.

7. Utilize methane generated to augment revenues.

1.1 Objectives:

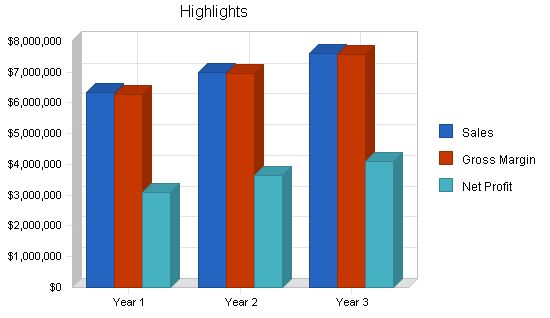

1. Achieve sales of over $6,000,000 ($11,000,000 with an additional 600 tons/day for Martin Creek) in the first twelve months of operations by increasing waste intake at Barton landfill and growing annually.

2. Build a recycling facility at Barton with at least one compactor/baler installed, with room for expansion to two compactor/balers.

3. Construct Martin Creek landfill and expand the landfill permit to include an additional 80 acres.

4. Purchase property to renovate an existing, abandoned rail spur near Barton landfill, with construction taking approximately ninety days.

5. Continuously market Martin Creek and Barton by reaching out to additional cities and hauling firms, including out-of-state sources.

1.2 Mission:

GER will haul waste from designated transfer stations to its landfills instead of directing it to other landfills. This benefits both parties by reducing costs for GER’s customers and increasing the waste stream for GER through more efficient transportation.

GER will also sell all recyclable materials and accept used vehicle tires at the landfills for income. Every aspect of this operation aims to increase cash flow and protect the environment. GER principals are committed to utilizing every resource to ensure environmental protection.

1.3 Keys to Success:

1. Focus on maximizing waste capacity at Martin Creek and Barton.

2. Process the waste stream efficiently and profitably while minimizing downtime and stoppages.

3. Operate the landfill operation efficiently and safely, prioritizing environmental care to increase profits.

4. Maintain a family-like atmosphere for all GER associates, including co-workers and customers.

GER will operate two landfills, Martin Creek and Barton, where waste will be sorted to remove 99% of recyclable materials. The remaining waste will be compacted into bales and deposited into the landfills.

After six months to one year, GER will capture methane gas produced in the landfills for commercial use and to generate electricity for landfill operations.

2.1 Company Ownership:

GER is a Missouri Corporation with three principals: one in charge of operations, one handling administration, and a corporate counsel. Investors will receive ownership percentage of the corporation, board of director seats, and first-out status in liquidity plans. Ownership percentage will be based on investment and contribution.

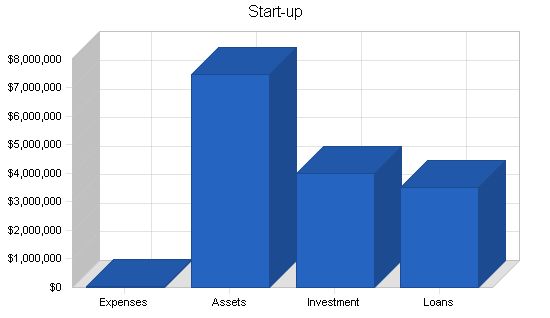

2.2 Start-up Summary:

The principals aim to secure $4,000,000 in net investor funds.

In phase one, funds will be used to close escrow on Martin Creek and Barton landfills. Hauling waste from transfer stations will immediately increase the waste stream and revenues.

For Martin Creek, compliance with state ordinances, installation of monitoring wells, submission of financial instrument and insurance, equipment leasing, and site development will take between seven and twelve months.

In phase two, conveyors, compactors, and baling systems will be installed. A permit for recycling incoming waste can be easily obtained as both states are eager to comply with federal recycling requirements. Construction of this facility will take approximately six months.

Each site will have a facility to house a compactor/baler and space for expansion to a second baling system. These facilities will be built after guaranteed cash flow and initial operations commence. Both landfills will have identical equipment.

The purchase includes rail spur sites and outlying transfer stations for both Barton and Martin Creek. Ongoing income will support the renovation of rail spurs.

Start-up Requirements:

Start-up Expenses:

– Legal: $10,000

– Insurance: $10,672

– Total: $20,672

Start-up Assets:

– Cash Required: $129,328

– Other Current Assets: $350,000

– Long-term Assets: $7,000,000

– Total Assets: $7,479,328

Total Requirements: $7,500,000

Start-up Funding:

Start-up Expenses to Fund: $20,672

Start-up Assets to Fund: $7,479,328

Total Funding Required: $7,500,000

Assets:

– Non-cash Assets from Start-up: $7,350,000

– Cash Requirements from Start-up: $129,328

– Additional Cash Raised: $0

– Cash Balance on Starting Date: $129,328

– Total Assets: $7,479,328

Liabilities and Capital:

– Liabilities:

– Current Borrowing: $3,500,000

– Long-term Liabilities: $0

– Accounts Payable (Outstanding Bills): $0

– Other Current Liabilities (interest-free): $0

– Total Liabilities: $3,500,000

– Capital:

– Planned Investment:

– Investment Amount: $4,000,000

– Other: $0

– Additional Investment Requirement: $0

– Total Planned Investment: $4,000,000

– Loss at Start-up (Start-up Expenses): ($20,672)

– Total Capital: $3,979,328

– Total Capital and Liabilities: $7,479,328

– Total Funding: $7,500,000

Company Locations and Facilities:

GER intends to purchase the adjacent 293 acres to Martin Creek for the following reasons. The Missouri and Southern Rail line runs through this property and a rail spur can be constructed to accept rail cars loaded with waste from distant sources like New York and Chicago. Owning this property will allow GER to haul waste from the rail spur to the landfill on company roads rather than using county roads. The property is an abandoned Barite strip mine with diminished land value, and may eventually be permitted as a landfill. It constitutes an additional buffer for the landfill.

Rail Spur Purchase at D&L Landfill:

An abandoned rail spur and receiving facility is situated a quarter of a mile from Barton landfill. GER will purchase this property in order to accept waste from distant municipalities. Funds for this purchase and its renovation have been allocated.

Services:

Martin Creek and Barton landfills are close, easy-access locations for St. Louis metropolitan area waste hauling firms to dispose of solid municipal waste. By sending GER road tractors to haul waste to its sites from more distant waste transfer stations, the tonnage starting with the first day of operations will be assured.

Receiving facilities are enclosed buildings into which all incoming waste is dumped. This waste will be hand sorted, removing 99% of all recyclables, then compacted, baled, and moved to the landfill.

The bales will form "bale cells" which include conduits for landfill gas capture. Each cell will be sealed to create an anaerobic environment for optimum gas generation and vector control.

After constructing the recycling facility and obtaining a permit, used tires will be crumbled and used throughout the landfill instead of crushed rock (inside bale cells to protect gas conduits, on landfill roads, and in the drainage system). Currently used tires generate an income of $1.75 to $2.00 per tire. Approximately 30,000 to 43,000 tires can be used per acre of landfill. This eliminates the cost of rock and requires no additional space for disposal.

Each bale cell will be wrapped with 60 mil polyvinyl chloride (PVC) sheets and sealed on all sides to trap and collect methane gas generated. Landfill gas is 55% methane (CH4), 45% carbon dioxide (C02), with trace amounts of nitrogen (N). The gas is cleaned, dried, and separated with membranes and filters. The methane can be used as fuel for electrical generators on site, providing substantial electricity savings.

Sales of electricity into the electrical grid are an alternate source of income for GER. Although large electric generators represent a significant capital investment, there is ample return on investment to warrant such expenditure. This option has the potential of adding approximately $4,000,000+ annually to the gross income.

Another process requiring different equipment and a significant capital investment is reforming the methane into methanol and food-grade C02. This process requires filtering, scrubbing, and bottling C02 for use in food and carbonated drinks, and methanol for use as fuel, solvents, and windshield washer fluid.

In bulk form, methanol sales can generate $0.48 per gallon. As a vehicle fuel, this product is called M-85 and contains a mixture of 85% methanol and 15% gasoline and is used in vehicles that have dual-configured engines. As the price of gasoline skyrockets, this method has more potential for an excellent adjunct profit center. All major automobile manufacturers offer assembly-line automobiles capable of using both M-85 and regular gasoline products in the same vehicle.

Service Description:

Landfill tipping fees are $34.00/ton ($11.33/yd) in St. Louis and nearby municipalities. In nearby Washington County, GER will provide landfill dumping for $28.00/ton ($9.33/yd). Tipping fees in Bond County, Illinois, the location of Barton landfill, are considerably lower at $18.00/ton ($6.50/yd) since the owners have not raised rates in over six years. GER will address rate increases at Barton after acquiring the business.

Competitive Comparison:

There are several types of competitors. Currently, there are two landfills operating in St. Louis County, and two in Illinois across the Mississippi River, twenty-five miles from downtown St. Louis. Waste trucks cross the river daily to the Illinois landfills. A round trip for a truck generally requires an hour and a half. At the landfills, roads are muddy in the fall, spring, and winter and dusty in the summer. Here is where the majority of waste truck breakdowns occur due to punctured tires, stalling, and mechanical problems. Both Martin Creek and Barton landfills will have paved dumping areas. Operation hours will be longer as well (6 AM to 8 PM daily and 6 AM to 2 PM on Saturdays). In the four hours after other landfills are closed, GER landfills will attract hauling firms whose trucks have been delayed during the day, or whose pickup routes are longer.

Sales Literature:

GER will prepare maps and information about Martin Creek and Barton for dissemination to users. Sales personnel will visit each nearby waste hauler with pricing, maps, and reminders of the facility. Especially noted will be hours of operation, free coffee and sodas for drivers, savings on driving distances, and all other benefits users can obtain when using GER’s facilities.

Technology:

GER intends to lease the most modern equipment for its operation. This will include powerful balers, shredders, and conveyors. Much of this equipment has been used in the recycling industry over the past 10-20 years and has been modified to handle normal waste stream material.

Initially, trucks, loaders, and tractors will be leased. In time, GER will purchase these vehicles. Should it opt to construct the methanol reformation facility, the vehicles GER purchases will have methanol fuel engines allowing the use of either methanol or conventional fuels.

New technology to assist in landfill gas generation continues to be developed. Cleaner gas, new processes, and techniques enhance GER’s capability of using landfill gas more effectively.

GER intends to install monitoring systems at the landfill to allow managers and officers to observe activity, verify trucks and loads by remote access and computers.

Future Services:

After the landfill has been operating for at least six months, GER will commence collecting methane gas to power electrical generators. During the first six months, the primary effort will be spent stabilizing the basic operation and working out start-up problems. Subsequently, decisions regarding the final utilization of methane will be made.

Marketing programs will commence to bring in baled waste from cities such as Chicago, Boston, Cleveland, New York, Washington, Providence, Hartford, Newark, and Philadelphia, as well as other Missouri municipalities and markets, such as Fort Leonard Wood, a U.S. Army base approximately 85 miles from the landfill in Rolla, Missouri. All of these locations have increasing problems with burgeoning waste and fewer available landfills. Rail-hauling baled waste is expected to be a significant profit center for GER.

New York City’s residential waste fees are normally $140.00 per ton (currently being held at an artificially low price by city government), whereas St. Louis fees are $34.00 per ton. Rail access at both GER landfills allows importation of this high-profit waste stream. Rail shipping costs are approximately $7.00 per ton, thus facilitating a reasonable means to import this profitable source of income in a manner that does not attract attention by using surface roads.

Income from methane gas generation will be gravy for an already lucrative waste and recycling business. Nationwide electrical and gasoline shortages add an urgency to utilizing this valuable byproduct. The American Methanol Institute has been helpful in providing information regarding methane reformation into methanol.

The cost of waste removal is expected to rise dramatically over the next decade. GER selected its landfill sites in rural locations, yet reasonably close to a major population center to capitalize on the growing need for landfills. Martin Creek and Barton are optimally situated to take advantage of the impending rising costs and landfill closure crisis.

GER intends to defuse any public concern by maintaining highly sanitary facilities that use ozone generators to eliminate odors, insects, and rodents. Baled waste does not cause the landfill to have the messy, littered appearance of traditional landfills. Baled waste is dense, and with paper and other recyclables removed, there is minimal blowing waste to litter the area. The "active" area is covered by earth and Polyvinyl Chloride (PVC) sheets, thus reducing odor, vectors, birds, and insects.

New York City Waste Stream:

Every five days, New York City’s garbage could fill Yankee Stadium. New York City has been wrestling with its garbage disposal for many years now. Its only landfill, Fresh Kills on Staten Island, recently closed. With this closure, its problem has reached crisis proportions. New York City Waste personnel are scrambling to find a "home" for their never-ending waste. It is the intent of Good Earth Resources to import a portion of this lucrative waste stream. New York City residents and businesses are charged in excess of $1.5 billion per year to dispose of their garbage. New York City pays $46.00 cubic yard ($140.00/ton) to dispose of its waste, while the rate in St. Louis is $11.33 cubic yard ($34.00/ton).

Currently, most of the New York City waste stream is exported via truck and barge. Necessarily, truck traffic passes through New Jersey and its residents, greatly dissatisfied with this traffic, continually seek means to stop it. Furthermore, destination states such as Virginia, Pennsylvania, and others also wish to limit waste truck traffic and waste importation. This presents an unusual opportunity for GER. By using rail-hauling and on-site rail spurs, there will be minimal awareness of imported waste. Income from 1,000 tons per day from New York City to each GER landfill will increase the return on investment significantly.

Market Analysis Summary:

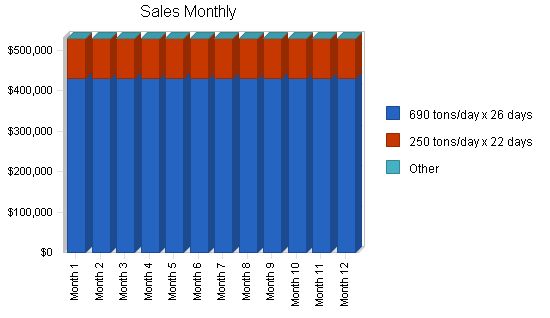

Barton landfill will be in a positive cash flow condition at the close of escrow. During the first month of operations, GER road tractors will haul waste from transfer stations in the cities of St. Louis and St. Charles to the landfill at a rate of 690 tons per day. This will supplement the local waste stream of 250 tons per day to bring the total to over 940 tons per day. An additional 600 tons per day is available from sources near Martin Creek landfill, and until Martin Creek construction is complete, GER intends to haul this waste to Barton as well.

With commitments from St. Louis waste collection firms and local hauling firms, GER expects to attain the break-even mark within the first 60 to 90 days after assuming ownership. Once this benchmark is passed, the primary focus will be on generating more customers both in the local St. Louis, Washington, Jefferson, and St. Francis Counties.

Martin Creek landfill will require a period of seven to twelve months of construction to become operational. By that time, GER will be able to direct sufficient waste from St. Louis and other municipalities to Martin Creek to create positive cash flow in the first month of operation.

Market Segmentation:

GER personnel plan to contact waste generators, such as food processing plants, breweries (Anheuser Busch), pet food manufacturers (Purina Dog Chow), restaurants, and financial institutions. Marketing personnel will contact each waste hauler in this part of Missouri and Illinois, alerting them to GER locations, hours, and rates.

Market Trends:

The most important market trend, landfill closures, favors GER. There are fewer and fewer landfills, while more and more families are moving to suburban locations, discouraging new landfills from opening and expediting the closure of those currently in use. The "nimby" (not in my back yard) cry prevents new landfills from being permitted or significantly slowing the process. State governments refuse to override citizens who adamantly fight landfill construction near their homes, even at the prospect of even higher waste collection charges. Neither Martin Creek nor Barton landfills have to experience a public hearing phase. Public opposition to landfills and transfer stations serves to push waste disposal costs higher with transportation to more distant landfills.

Of the companies focused on the profitable business of waste removal, only a minor number have developed an efficient method to remove the gas generated from buried waste. Ninety-eight percent of landfills use earth as a cover ("cut and fill") rather than PVC covering. This reduces gas purity and volume. Older waste burial practices cause gas retrieval to be difficult and expensive, while the bale cell system GER intends to use will capture the majority of the gas. Sealed cells reduce leachate leakage and water table contamination. Gas production will provide revenues for many years to come.

The U.S. Environmental Protection Agency’s Office of Solid Waste identifies by name and location Non-Hazardous Waste landfills throughout the United States and U.S. territories every several years. 1986 was the first year this census was taken, and there were 7,683 landfills identified. In 1992, the document was updated and showed a decline to 5,345 landfills. In 1995, the document was updated once again and showed a further decline in landfills to 3,581. This report substantiates the increasing value of a landfill permit and the increasing difficulty to obtain a permit to dispose of municipal waste. The trend is obviously favorable for owners of landfills that are available to accept waste. It will not be many years before rates increase substantially, and even local waste fees will skyrocket.

Value Enhancing Factors:

As mentioned, landfills are becoming more and more scarce, especially on the eastern seaboard. Those possessing permitted landfills own virtual gold mines as values continue to rise. Martin Creek landfill has 284 acres with 42 acres currently permitted by the Missouri Department of Natural Resources. Barton Sanitary landfill has 300 acres and a permitted area of 65 acres and is permitted by the State of Illinois Environmental Protection Agency.

Martin Creek will treble in valuation when construction is complete. A typical landfill with final permits ready for operation carries a price tag from $6-7 million, and, in some cases, more.

Over the past decade, recycling has reached every household in the United States. Many municipalities have mandatory recycling laws. It makes economic sense for people to remove recyclables from the waste stream. This is a practice that can help preserve the earth’s resources. Even when citizens remove the majority of recyclables, an operation such as is proposed in this plan will remove an additional 25% of the volume in white paper, cardboard, glass, plastic, ferrous, and aluminum. GER is performing the ultimate "recycling" by enclosing the baled waste and capturing the gas to be used for productive, profitable means. By using this often-wasted energy, our national dependency on fossil fuels may diminish, albeit slightly. Each bale cell generates methane for years after closure.

Several factors, then, accrue to the benefit of GER. Owning landfills with rail access in the heartland of the USA, landfill closures, population growth, rising waste removal costs, technology advances, and continued fossil fuel dependency add up to excellent market growth and exemplary value in return for each invested dollar and hour of effort. Landfill gas capture will provide income long after the waste operation ceases.

Target Market Segment Strategy:

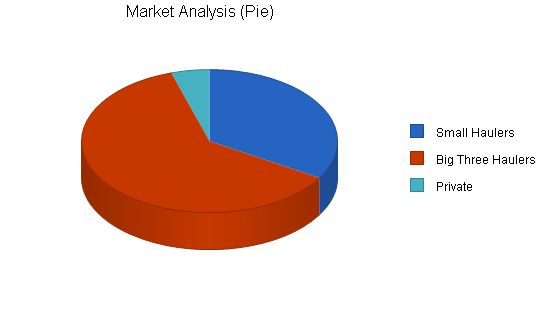

Market Analysis

| Market Analysis | |||||||

| Year 1 | Year 2 | Year 3 | Year 4 | Year 5 | |||

| Potential Customers | Growth | CAGR | |||||

| Small Haulers | 15% | 700 | 805 | 926 | 1,065 | 1,225 | 15.02% |

| Big Three Haulers | 10% | 1,280 | 1,408 | 1,549 | 1,704 | 1,874 | 10.00% |

| Private | 25% | 100 | 125 | 156 | 195 | 244 | 24.98% |

| Total | 12.59% | 2,080 | 2,338 | 2,631 | 2,964 | 3,343 | 12.59% |

4.2.2 Market Growth

Associated Waste and USA Waste Technologies are the two major firms in the waste business nationwide. Both are NYSE listed and engage in collecting residential and commercial waste, operating transfer stations, and managing landfills.

The metropolitan St. Louis area, encompassing St. Louis city and County, St. Charles County, and Jefferson County, generates an estimated daily waste of 12,000 to 16,000 yards. GER can immediately handle 10% of this waste stream daily without competition, with expectations of capturing a larger percentage over time.

The waste collection services in the local counties of Washington, St. Francois, Jefferson, St. Genevieve, Iron, and Madison contribute to the overall waste volume.

Washington County trucks travel 104 miles round trip to a transfer station in St. Genevieve City, St. Genevieve County, Missouri, which is then taken to DeSoto, Illinois, covering 146 miles.

St. Francois trucks travel 92 miles round trip to a transfer station in St. Genevieve city, St. Genevieve County, Missouri, which is then trucked to DeSoto, Illinois. St. Genevieve trucks go to a nearby transfer station in St. Genevieve City, St. Genevieve County, Missouri, before being trucked to DeSoto, Illinois.

Jefferson County trucks transport waste to a transfer station in Barnhart, Jefferson County, then either to Weber Landfill in St. Louis (a round trip of 70 miles) or across the Mississippi to East St. Louis, Illinois (a round trip of 90 miles).

Iron County waste trucks pick up waste and drive to Fredericktown Transfer Station (a round trip of 56 miles), which is then trucked to Butler County Landfill in Poplar Bluff, Missouri (a round trip of 80 miles).

Madison trucks pick up waste and drive to Fredericktown, Madison County Transfer Station, where it is trucked to Butler County Landfill in Poplar Bluff, Missouri.

Comparatively, Washington County trucks would only travel 18 miles round trip to Martin Creek instead of 104 miles. St. Francois County trucks would travel 36 miles round trip to Martin Creek instead of 92 miles. St. Genevieve County trucks would travel 72 miles round trip to Martin Creek instead of 144 miles. Jefferson County trucks would travel 22 to 75 miles round trip to Martin Creek instead of 90 miles. Iron County trucks would travel 44 miles round trip to Martin Creek instead of 56 miles. Madison County trucks would travel 68 miles round trip to Martin Creek instead of 80 miles.

Using Martin Creek for waste disposal would save time and mileage for all these counties, resulting in cost savings. There are currently no long-term contracts in place that would prevent a switch to Martin Creek.

The daily waste production of these counties is as follows:

- Washington: 80-120 yards.

- St. Francois: 250-300 yards.

- Jefferson: 2,000 yards.

- St. Genevieve: 250 yards.

- Iron: 60 yards.

- Madison: 60-80 yards.

- Total: 2,700 to 2,800 yards per day from local counties.

Sales Forecast

The following table and chart outline our proposed sales, divided between the estimated sales generated by each of the two landfills.

Unit Sales

– 690 tons/day x 26 days: Year 1 – 215,280, Year 2 – 241,750, Year 3 – 267,350

– 250 tons/day x 22 days: Year 1 – 66,000, Year 2 – 66,000, Year 3 – 66,000

– Other: Year 1 – 0, Year 2 – 0, Year 3 – 0

– Total Unit Sales: Year 1 – 281,280, Year 2 – 307,750, Year 3 – 333,350

Unit Prices

– 690 tons/day x 26 days: Year 1 – $24.00, Year 2 – $24.00, Year 3 – $24.00

– 250 tons/day x 22 days: Year 1 – $18.00, Year 2 – $18.00, Year 3 – $18.00

– Other: Year 1 – $0.00, Year 2 – $0.00, Year 3 – $0.00

Sales

– 690 tons/day x 26 days: Year 1 – $5,166,720, Year 2 – $5,802,000, Year 3 – $6,416,400

– 250 tons/day x 22 days: Year 1 – $1,188,000, Year 2 – $1,188,000, Year 3 – $1,188,000

– Other: Year 1 – $0, Year 2 – $0, Year 3 – $0

– Total Sales: Year 1 – $6,354,720, Year 2 – $6,990,000, Year 3 – $7,604,400

Direct Unit Costs

– 690 tons/day x 26 days: Year 1 – $0.30, Year 2 – $0.12, Year 3 – $0.12

– 250 tons/day x 22 days: Year 1 – $0.32, Year 2 – $0.15, Year 3 – $0.15

– Other: Year 1 – $0.00, Year 2 – $0.00, Year 3 – $0.00

Direct Cost of Sales

– 690 tons/day x 26 days: Year 1 – $63,722, Year 2 – $28,171, Year 3 – $31,154

– 250 tons/day x 22 days: Year 1 – $21,300, Year 2 – $9,600, Year 3 – $9,600

– Other: Year 1 – $0, Year 2 – $0, Year 3 – $0

– Subtotal Direct Cost of Sales: Year 1 – $85,022, Year 2 – $37,771, Year 3 – $40,754

Management Summary

The initial management team consists of the founders and a small group of professionals. As GER expands, additional consulting help, engineering, sales, and marketing staff will be added.

6.1 Organizational Structure

GER has two founding principals. One is responsible for operations while the other focuses on administrative/sales. Supervisors will be hired to handle day-to-day operations.

Don Smith, one of the principals, will have his sons trained and take on supervisory positions at the landfills.

6.2 Management Team

Co-founder Don Smith owns and operates Smith Environmental Services, a large subsurface soil remediation business in Missouri. He has extensive experience and knowledge of equipment used in GER operations.

Co-founder John App has a sales and management background. He will operate the sales and marketing team for GER and provide administrative support.

G. Calvin Rathbone serves as Corporate Counsel and has specialized in civil litigation and environmental issues. He will assist with the New York City marketing effort.

Curtis E. Smith has 23 years of experience in landfill operations and will be a landfill supervisor.

6.3 Management Team Gaps

GER will hire a qualified bookkeeper and financial manager to handle fiscal and payroll management. Additional management personnel will be recruited as the operation grows.

GER aims to employ permanent sales personnel to maintain relationships with waste commissions in major cities.

6.4 Personnel Plan

The following table summarizes GER’s personnel expenditures for the first three years at Barton Landfill:

Office Clerks (2) @ $76.00/Day: Year 1 – $47,424, Year 2 – $49,972, Year 3 – $52,470

Operators (6) @ $100/day: Year 1 – $187,200, Year 2 – $196,560, Year 3 – $206,388

Laborers (1) @ $80/day: Year 1 – $24,960, Year 2 – $26,208, Year 3 – $27,518

Maintenance Mechanic (1) @ $100/day: Year 1 – $31,200, Year 2 – $32,670, Year 3 – $34,398

Supervisors (3) @ $140/day: Year 1 – $131,040, Year 2 – $137,592, Year 3 – $144,471

Managers (2) @ $5000/month: Year 1 – $120,000, Year 2 – $126,000, Year 3 – $132,300

Total People: 15

Total Payroll: Year 1 – $541,824, Year 2 – $569,002, Year 3 – $597,545

Hello!

I’m Andrew Brooks, a seasoned finance consultant from the USA and the mind behind phonenumber247.com.

My career is built on a foundation of helping individuals and businesses thrive financially in an ever-changing economic landscape. At phonenumber247.com, my aim is to demystify the complex world of finance, providing clear, actionable advice that can help you navigate your financial journey with confidence. Whether it’s personal finance management, investment strategies, or understanding the nuances of market dynamics, I’m here to share insights and tools that can propel you towards your financial goals.

Welcome to my digital space, where every piece of advice is a step closer to financial clarity and success!